- Removed: 11/2005 -

The Coldside now lives with Dan at

Run-Down.com

The "stock" idler pulley setup on the Coldside has always been a weak link. One bolt holding it all on, no good way to tension, and the fact that if/when you lose that one bolt, you lose your whole pulley setup... there was room for improvement. Thanks to Edward Smith and "Hamez" of the BRP Forum, I was able to put together something a little more sophisticated.

Lexan prototype of the new idler system.

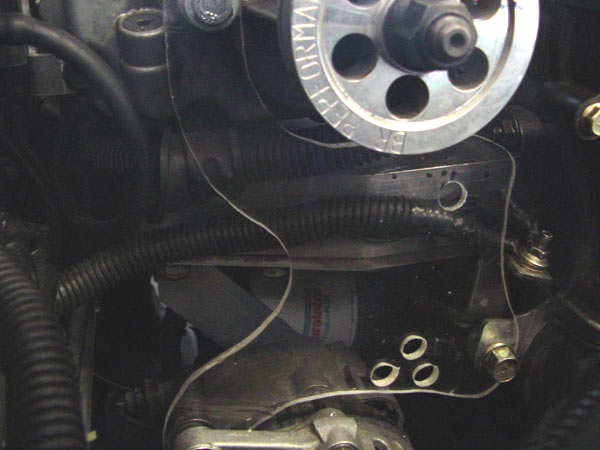

This photo doesn't quite show the three points of attachment defining the plane of the new pulley plate. Instead

of using the alternator adjustment bolt, now the alt. is positioned as far down in the range of travel as possible.

The water pump bolt on the right provides strenght to the system. And on top, the bolt through the front of the blower

defines the plane.

Another view of the lexan prototype.

The clear lexan allowed me to figure out exactly where I needed to drill each hole. For example, the top pulley hole

(empty in this shot) was dangerously close to my fuel line. This is a bad angle, but I was able to put that

hole right between the fuel line and the alternator ground wire.

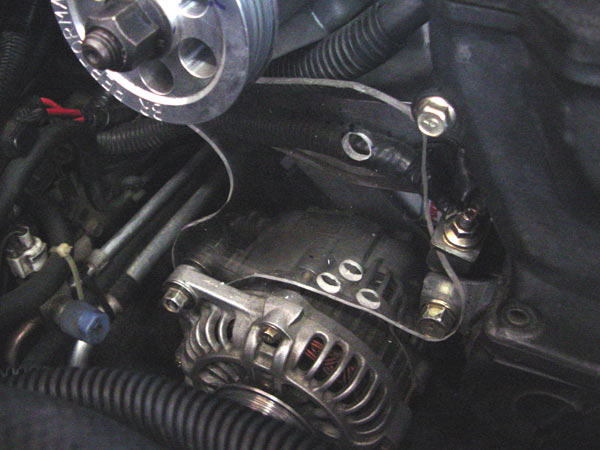

Water pump bolt and the alternator ground.

One thing about this new pulley system I wanted to maintain was usability. The old system was anything

but usable. I wanted quick belt changes, lots of belt wrap, and no problems adjusting tension.

I didn't want any stock parts to become hidden out of reach, thus, you see the alternator ground in its

final position in this pic. It just needed to be bent a little to the right.

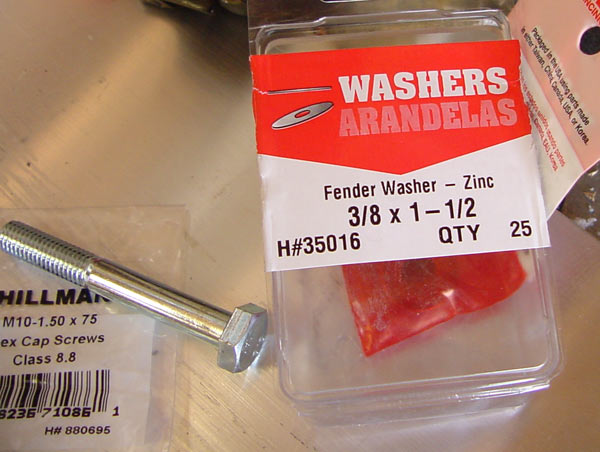

Parts needed to make your own revised pulley system.

Parts needed:

- At least 8"x12" of .25" thick aluminum for the plate

- At least two M10-150x75mm bolts (one for the idler, one for the tensioner)

- At least one pack of 3/8" fender washers (25-30 of them total)

- One idler (use a spare JRSC nylon one) and a VW timing belt tensioner

- Nyloc bolts for the pulleys

- Some method of cutting the aluminum. A jigsaw with a metal cutting blade and some cutting wax works well.

- A new belt. I used a Gates K080635.

The tensioner and the idler.

That's one JRSC nylon pulley in the back, and one VW timing belt tensioner. It tensions around a cam bolt with a little

tool (the red handle to the right). This is an unfortunate picture in that you can't see the offset of the hole in the

VW pulley. These both needed to be offset from the idler plate by a decent distance, and as you can see, I used only

the most hightech spacers available. As for the VW tensioner, it's supposedly for an early 90s VW Golf 1.8. I found

a listing at autohausaz.com for several pulleys and just ordered the one I thought looked closest. It was part

number 026-109-243e.

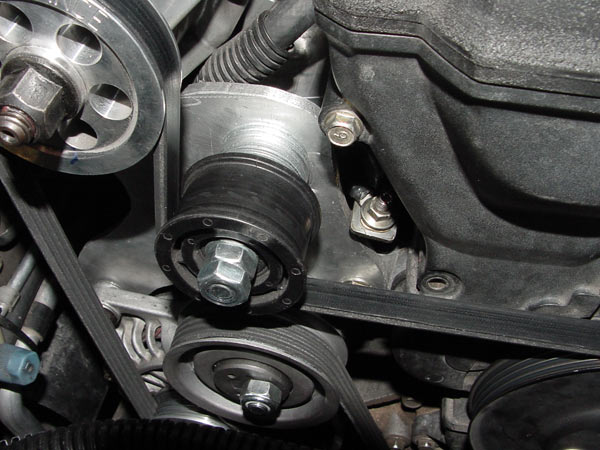

The completed idler system installed.

Anyone familiar with the Coldside idler system should be immediately impressed. This new system gives you more

than 180* of belt wrap on both the blower and the alternator. No more belt squeal, no more crazy 135+ lbs of belt

tension, and most importantly, no more threat of losing the whole pulley system if one bolt breaks.

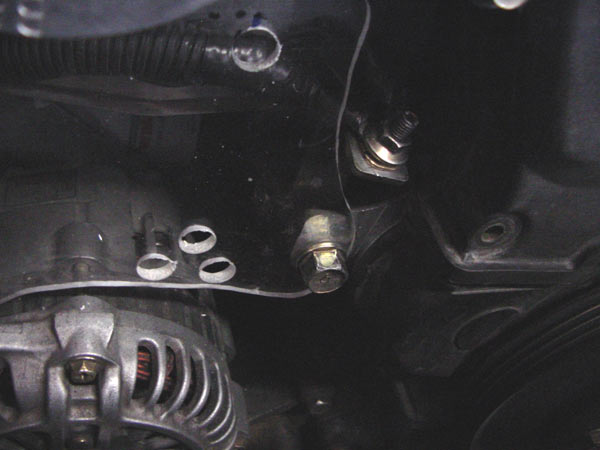

The idler (top) and the tensioner (bottom) installed.

At the bottom, you can see the offset of the VW cam pulley pretty nicely. It's tensioned through the holes

on the left. On the top pulley, you can see the stack of washers behind it, giving it a little offset to keep

the belt lined up perfectly.

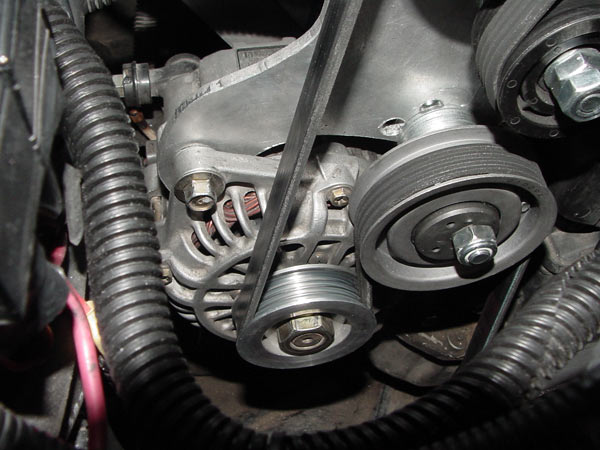

Notice the straight belt path.

This shot shows the belt lined up perfectly. I also highlighted (very lightly) two points of attachment. On the

bottom is the hole that used to have the alternator tensioner bolt. It now just has a single bolt that holds it in

place on the new bracket. On the top, you see the bolt going through the blower. This bolt is not for strength, it

only defines the plane. Notice how it's spaced out with washers behind the bracket.

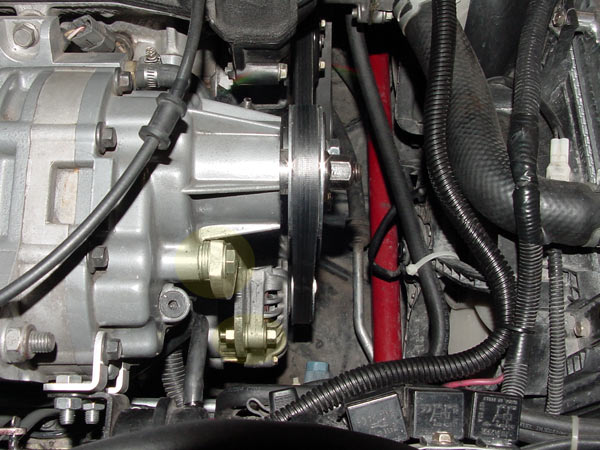

Belt wrap on the alternator.

Lack of alternator belt wrap was a weak point of the original pulley system. I dare the alternator

to find a way to slip now! That is a lot of belt wrap.

Finally, this is how we tension.

That's it. One special tool twists one pulley. No fiddling with pinch bolts or tweaking alternator brackets.

One special tool, and one bolt to tighten (the one going through that VW pulley). Simple. Easy. Uncomplicated. Just

like the Coldside.

Site Navigation

Latest Blog Posts

CarbonMiata Vent Window Install/Review

Posted on Mon, 30 Jan 2023 01:47:44 +0000

After waiting 23 years, there's finally a pretty vent window kit on the market for the NA/NB Miata. Unfortunately, it doesn't actually work well.

After waiting 23 years, there's finally a pretty vent window kit on the market for the NA/NB Miata. Unfortunately, it doesn't actually work well.

Read more...

Period-Correct 90s Rear Speakers

Posted on Mon, 11 Oct 2021 02:12:26 +0000

Sharka's rear package tray now holds more than just a rollbar. A set of 90s speakers is the next upgrade for the little blue and white boi.

Sharka's rear package tray now holds more than just a rollbar. A set of 90s speakers is the next upgrade for the little blue and white boi.

Read more...

GV Tail Light Upgrade

Posted on Tue, 28 Sep 2021 02:05:06 +0000

TLDR; LEDs are brighter, who knew?

TLDR; LEDs are brighter, who knew?

Read more...

Mona Visits Joshua Tree

Posted on Sat, 26 Jun 2021 03:21:12 +0000

Mona checks out the curious multi-armed residents of Joshua Tree National Park

Mona checks out the curious multi-armed residents of Joshua Tree National Park

Read more...

KINOD 15

Posted on Sun, 20 Jun 2021 22:49:33 +0000

Mona and I made the pilgrimage to SoCal for the 15th Anniversary KINOD Event.

Mona and I made the pilgrimage to SoCal for the 15th Anniversary KINOD Event.

Read more...

Products sold on this site are for Off-road and Competition use only. This website intended solely to provide general guidance on matters of interest for the personal use of the Reader of this Page, who accepts full responsibility for its use. All products as well as information provided "as is," with no guarantee of completeness, accuracy, or timeliness, and without warranty of any kind, express or implied, including, but not limited to, the warranties of performance, merchantability, and fitness for a particular purpose.